| Place of Origin: | CHINA |

|---|---|

| Brand Name: | NTH |

| Model Number: | OMSR-B1, OMSR-B2, OMSR-B3, OMSR-B4, OMSR-B5, OMSR-B6, |

| Minimum Order Quantity: | 1 set |

| Price: | Negotiation |

| Packaging Details: | Good and firm package is suitable for the sea and air shipping |

| Delivery Time: | 3work days available |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 1000 sets/M |

| Product Name: | SELF CENTERING STEADY REST OMSR-B MODEL | Material: | Cast Steel |

|---|---|---|---|

| Function: | Feature: | Creative Design,Wide Clamping | |

| Usage: | Fixture/Gripping/Prop Up | Service: | Cylinders Differing From Standard Available On Request |

| Highlight: | hydraulic self centering steady rest, lathe steady rest |

||

SELF CENTERING STEADY REST OMSR-B MODEL

SELF CENTERING STEADY REST OMSR-B MODEL

MECHANISM FOR OPENING THE ARMS OF THE STEADY REST WITHOUT SPRINGS AND FREE FROM WEAR.AND ANTI-VIBRATION DESIGN FOR MACHINING.

OPTION OF LUBRICATION

Manual lubrication: Low cost solution for medium working conditions and low swarf.

Central lubrication: For heavy working conditions and high build up of swarf

Central lubrication oil and air: For heaviest cutting conditions with high built up of swarf,dust or coolant

OPTION OF LUBRICATION

Omatei rollers (precision class P05) specially developed for our Steady Rests

Special sealing ensures highest precision and service life

Standard equipment: 1 set of cylindrical rollers

Option: Spherical rollers (for travelling Steady Rests)

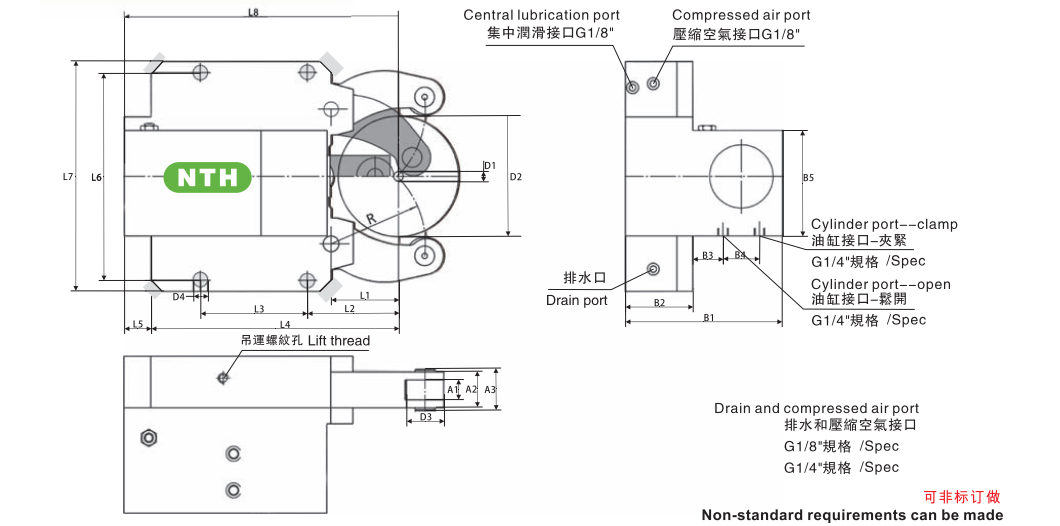

| NTH-OMSR Model Spec | OMSR-B1 | OMSR-B2 | OMSR-B3 | OMSR-B4 | OMSR-B5 | OMSR-B6 |

|---|---|---|---|---|---|---|

| D1 (mm) | 50 | 50 | 90 | 125 | 200 | 230 |

| D2 (mm) | 200 | 310 | 350 | 460 | 530 | 630 |

| D3 (mm) | 47 | 62 | 62 | 80 | 100 | 100 |

| D4 (mm) | 18 | 23 | 23 | 27 | 27 | 35 |

| L1 (mm) | 103 | 160 | 180 | 175 | 283 | 290 |

| L2 (mm) | 138 | 178 | 198 | 215 | 320 | 375 |

| L3 (mm) | 135 | 270 | 270 | 330 | 440 | 500 |

| L4 (mm) | 335 | 510 | 530 | 709 | 897.5 | 1020 |

| L5 (mm) | 37.5 | 102.5 | 102.5 | 91 | 103.5 | 110 |

| L6 (mm) | 262 | 400 | 400 | 610/640 | 650 | 855 |

| L7 (mm) | 290 | 440 | 440 | 680 | 710 | 930 |

| L8 (mm) | 372.5 | 612.5 | 632.5 | 800 | 1001 | 1130 |

| A1 (mm) | 25 | 29 | 29 | 29 | 32 | 32 |

| A2 (mm) | 45 | 75 | 75 | 75 | 100 | 100 |

| A3 (mm) | 52 | 83 | 83 | 83 | 112 | 110 |

| B1 (mm) | 198 | 325 | 325 | 350 | 405 | 487 |

| B2 (mm) | 85 | 145 | 145 | 145 | 180 | 190 |

| B3 (mm) | 38 | 79.5 | 79.5 | 74.5 | 191 | 191 |

| B4 (mm) | 46 | 66 | 66 | 96 | 50 | 50 |

| B5 (mm) | 133 | 170 | 170 | 185 | 260 | 260 |

| Work pressure Min./Max. (bar) | 8/60 | 8/80 | 8/80 | 8/70 | 8/70 | 8/70 |

| Max clamping force of the roller (daN) | 1000 | 2000 | 2000 | 3000 | 4000 | 4000 |

| Position accuracy within the clamping range (mm) | 0.04 | 0.06 | 0.06 | 0.06 | 0.08 | 0.08 |

| Repeatability accuracy (mm) | 0.007 | 0.01 | 0.01 | 0.01 | 0.02 | 0.02 |

| Max line speed of the roller (m/min) | 725 | 600 | 600 | 560 | 570 | 570 |

| Weight(KG) | 47.8 | 174.8 | 177.8 | 482.8 | 1000 | 1300 |

Cylinders differing from standard available on request,Subject to technical changes.