| Place of Origin: | CHINA |

|---|---|

| Brand Name: | OMATEI |

| Model Number: | LL-26,LL-30,LL-42,LL-52,LL-60,LL-60,LL-80 |

| Minimum Order Quantity: | 1 set |

| Price: | Negotiation |

| Packaging Details: | Good and firm package is suitable for the sea and air shipping |

| Delivery Time: | 3work days available |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 1000 sets/M |

| Product Name: | Forged LL Collet Chuck 1 Ideal Choice For Gripping And Fixtures | Material: | Forged |

|---|---|---|---|

| Function: | Feature: | High Quality /High Precision | |

| Usage: | Refer To The Specification | Service: | ODM/OEM Is Available |

| Highlight: | Gripping Fixtures Collet Chuck, Forged LL Collet Chuck, 1 LL Collet Chuck |

||

Forged LL Collet Chuck 1 Ideal Choice For Gripping And Fixtures

It‵s a push type collet chuck, it’s suitable for turning machine, or CNC, or other tools machines.

Construction of high rigidity and high clamping accuracy and high rotary speed.

The connecting spec is same as other "Through-hole power chuck", No need change the "Draw tube"

It goes with the DIN 6343 standard collet.

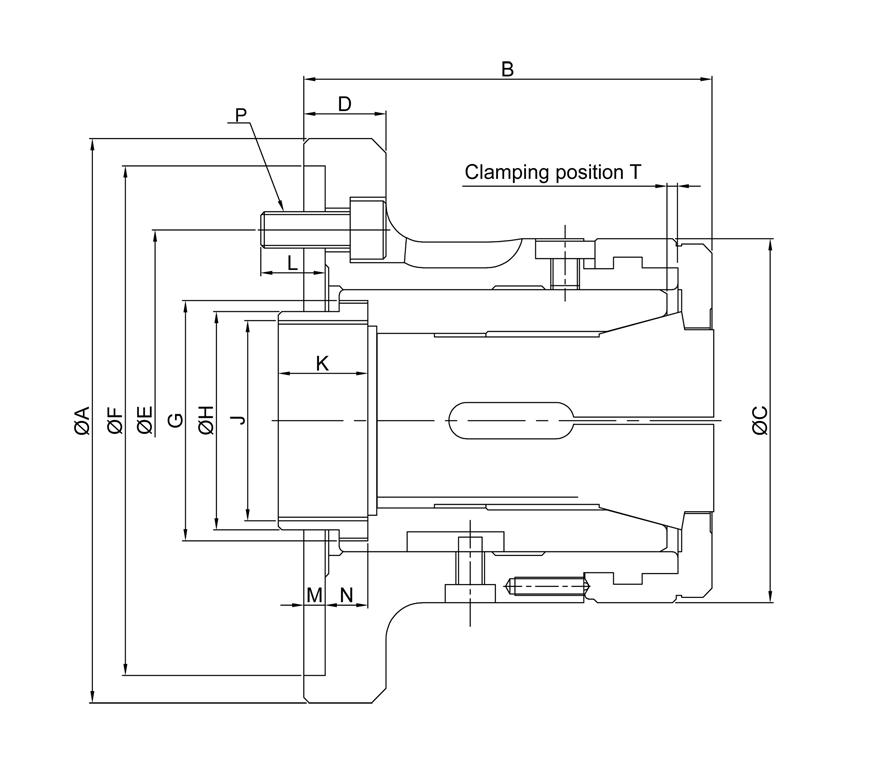

(unit: mm)

| Spec/Model | Plunger stroke mm | Grip Round | Grip Hex. | Grip Sq. | Max.D.B.Pull kgf | Max clamping force kgf |

| LL-26 | 4.5 | 3~26 | 4~22 | 4~18 | 17.6(1800) | 37.9(3870) |

| LL-30 | 4.5 | 3~30 | 4~26 | 4~20 | 19.6(2000) | 42.1(4300) |

| LL-42 | 6 | 3~42 | 6~36 | 6~29 | 24.5(2500) | 52.9(5400) |

| LL-52 | 6 | 5~52 | 8~45 | 7~36 | 27.4(2800) | 59.0(6020) |

| LL-60 | 6 | 5~60 | 8~52 | 7~42 | 29.4(3000) | 63.7(6500) |

| LL-60 | 6 | 5~60 | 8~52 | 7~42 | 29.4(3000) | 63.7(6500) |

| LL-80 | 6 | 20~80 | 18~69 | 15~56 | 34.3(3500) | 71.5(7300) |

| Spec/Model | Max RPM | Inertia moment kg*m2 | Weight kg | Matched Collet | Matched cylinders | Max Pressure Mpa(kgf/cm2) |

| LL-26 | 8000 | 0.04 | 4.3 | 161E | H-0928 | 2.6(26) |

| LL-30 | 8000 | 0.038 | 4.2 | 163E | H-1036 | 2.9(29) |

| LL-42 | 6000 | 0.06 | 6.9 | 173E | H-1246 | 2.9(29) |

| LL-52 | 6000 | 0.101 | 14.3 | 177E | H-1552 | 2.3(23) |

| LL-60 | 5000 | 0.098 | 14.1 | 185E | H-1875 | 1.8(18) |

| LL-60 | 5000 | 0.126 | 16.3 | 185E | H-1875 | 1.8(18) |

| LL-80 | 4000 | 0.108 | 17.8 | 193E | H-2091 | 1.6(16) |

| Spec/ Model | A | B | C | D | E | F(H6) | G | H |

J Max | K | L | M | N | P | T |

| LL-26 | 120 | 100 | 85 | 23 | 82.6 | 110 | M50x1.5 | 45 | M40x1.5 | 15 | 16 | 4 | 10.2 | 3~M10 | 2.3 |

| LL-30 | 120 | 100 | 85 | 23 | 82.6 | 110 | M50x1.5 | 45 | M40x1.5 | 15 | 16 | 4 | 10.2 | 3~M10 | 2.3 |

| LL-42 | 155 | 120 | 100 | 23 | 104.78 | 140 | M66x1.5 | 60 | M55x2.0 | 25 | 18 | 6 | 11.9 | 3~M10 | 3.1 |

| LL-52 | 185 | 145.5 | 130 | 30 | 133.35 | 170 | M90x1.5 | 66.7 | M60x2.0 | 30 | 18 | 6 | 17.9 | 6~M12 | 3.1 |

| LL-60 | 185 | 145.5 | 130 | 30 | 133.35 | 170 | M90x1.5 | 80 | M74x2.0 | 30 | 18 | 6 | 17.9 | 6~M12 | 3.1 |

| LL-60 | 235 | 142 | 130 | 32 | 171.45 | 220 | M90x1.5 | 80 | M74x2.0 | 30 | 20 | 6 | 19.9 | 6~M16 | 3.1 |

| LL-80 | 235 | 163 | 156 | 32 | 171.45 | 220 | M114x2.0 | 99 | M90x2.0 | 27.5 | 20 | 6 | 23.4 | 6~M16 | 6.1 |

Note: Subject to technology changes without prior information;

Non-standard requirements can be made.