| Place of Origin: | CHINA |

|---|---|

| Brand Name: | NTH |

| Model Number: | SCT-04,SCT-05,SCT-06,SCT-07,SCT-08,SCT-09,SCT-10 |

| Minimum Order Quantity: | 1 set |

| Price: | Negotiation |

| Packaging Details: | Good and firm package is suitable for sea and air shipping |

| Delivery Time: | 3 work days |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | -- |

| Product Name: | SCT 2 Jaw Scroll Chuck Front And Back Mounted | Material: | Cast Iron |

|---|---|---|---|

| Function: | Fixture/Gripping | Feature: | High Precision/Stable/High Quality |

| Usage: | Refer To The Specification | Service: | ODM/OEM Is Accpetable |

| Highlight: | manual lathe chuck, cnc lathe chuck |

||

SCT 2 Jaw Scroll Chuck Front And Back Mounted

1.Plain back

2.Standard accessories: 1 set outside solid jaws and 1 set inside solid jaws

3.High accuracy on clamping repeatability

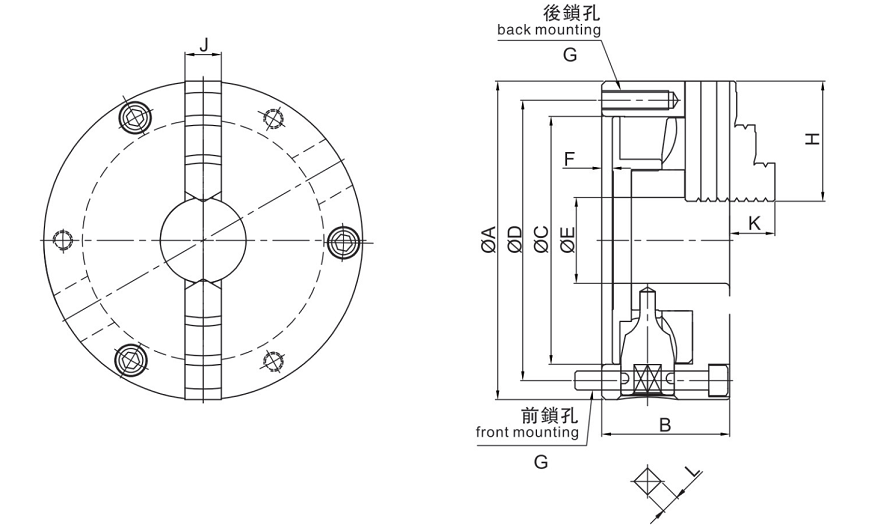

Specification UNIT:mm

| Model/Spec | Max. Allowable Torque N*m | Max. Gripping Force KN | Weight Kg | RPM | O.D Clamping Range mm | I.D. Clamping Range mm |

| SCT-04* | 44 | 12 | 3.1 | 2500 | 3-90 | 32-84 |

| SCT-05* | 63 | 15 | 4.4 | 2500 | 3-110 | 35-100 |

| SCT-06 | 88 | 31 | 11.4 | 2000 | 3-160 | 48-150 |

| SCT-07 | 107 | 31 | 12.2 | 2000 | 4-180 | 56-170 |

| SCT-08 | 128 | 33 | 16.2 | 2000 | 4-180 | 56-170 |

| SCT-09 | 147 | 37 | 21.2 | 2000 | 5-220 | 62-210 |

| SCT-10 | 176 | 46 | 28 | 1800 | 6-260 | 70-250 |

| Model/Spec | A | B | C | D | E | F | G | H | J | K | L |

| SCT-04* | 112 | 58 | 80 | 95 | 24 | 4.5 | 3(4)-M8x1.25P | 42 | 15 | 17 | 8 |

| SCT-05* | 132 | 60 | 100 | 115 | 32 | 4.5 | 3(4)-M8x1.25P | 50 | 20 | 19 | 8 |

| SCT-06 | 167 | 66 | 130 | 147 | 45 | 5 | 3-M10x1.5P | 70 | 20 | 31 | 10 |

| SCT-07 | 193 | 76 | 155 | 172 | 58 | 5 | 3-M10x1.5P | 84 | 25 | 28 | 11 |

| SCT-08 | 203 | 76 | 160 | 176 | 58 | 5 | 3-M10x1.5P | 84 | 25 | 28 | 11 |

| SCT-09 | 233 | 84 | 190 | 210 | 70 | 5.5 | 3-M12x1.75P | 84 | 25 | 28 | 12 |

| SCT-10 | 273 | 86 | 230 | 250 | 89 | 5.5 | 3-M12x1.75P | 105 | 28 | 33 | 12 |

*Note:The front mounting bolts are 4 pcs

Special after-sales service promise

For all NTH precision manual chuck, our company guarantee the following value-added services:

1. Free inspection after returning to our factory.

2. Free grinding for the clamping arc of chuck jaws to make the jaws meet the original factory precision standard.

3. To provide maintenance plan free.

4. For the above services, no matter how long the manual chuck is used, users only need to pay the round-trip freight.

5. If any damaged parts of the manual chuck need changing, users just pay for the new parts.

Subject to technology changes without prior information

Non-standard requirements can be made