| Place of Origin: | CHINA |

|---|---|

| Brand Name: | OMATEI |

| Model Number: | 3A1,2C1,1C1,18C1,4C1,5C1,6C1,7C1,8C1,3A2, etc |

| Minimum Order Quantity: | 1 set |

| Price: | Negotiation |

| Packaging Details: | Good and firm package is suitable for the sea and air shipping |

| Delivery Time: | 3work days available |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 1000 sets/M |

| Product Name: | PTG EXPANDING MANDREL | Material: | Cast Steel |

|---|---|---|---|

| Function: | Feature: | Product Name: PTG EXPANDING MANDREL Material: Cast Steel Usage: Fixture/Gripping Feature: | |

| Usage: | Fixture/Gripping | Service: | ODM/OEM Is Accpetable |

| Highlight: | hydraulic collet chuck, cnc collet chuck |

||

PTG EXPANDING MANDREL

PTG EXPANDING MANDREL

Brand:NTH

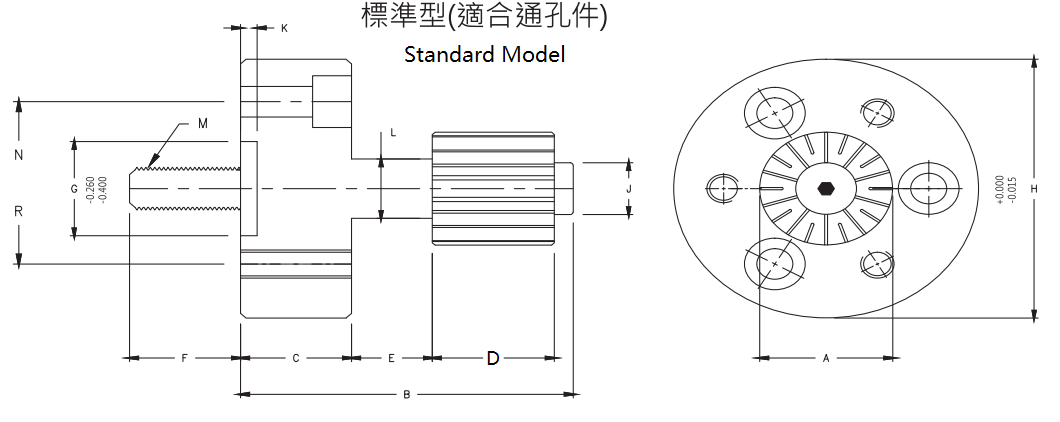

Large expansion range up to 0.6mm.

Double-angle principle allows for fast loading/unloading of components.

Greater holding power by applying pressure evenly along the length of the sleeve.

Guaranteed accuracy of 0.015mm.

Standard Model | 3A1 | 2C1 | 1C1 | 18C1 | 4C1 | 5C1 | 6C1 | 7C1 | 8C1 |

|---|---|---|---|---|---|---|---|---|---|

A ( Dia) | Min:12.5 | Min:16.0 | Min:22.0 | Min:28.5 | Min:41.0 | Min:63.5 | Min:76.2 | Min:89.0 | Min:130.0 |

| B | 60 | 66 | 72 | 79 | 84 | 109 | 118 | 133 | 153 |

| C | 20 | 20 | 20 | 20 | 20 | 25 | 25 | 30 | 30 |

| D | 22 | 27 | 32 | 38 | 43 | 51 | 57 | 63.5 | 79.5 |

| E | 14.6 | 15 | 15.5 | 15.3 | 14.8 | 25.3 | 24.7 | 25.2 | 24.6 |

| F | 20 | 22 | 30 | 31 | 36 | 36 | 37 | 47 | 22 |

| G | 40 | 40 | 40 | 40 | 40 | 60 | 60 | 100 | 100 |

| H | 75 | 75 | 75 | 75 | 75 | 120 | 120 | 180 | 180 |

| J | 11 | 15 | 20 | 26.5 | 37.5 | 55 | 74.5 | 86.5 | 124 |

| K | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| L | 12.6 | 14.1 | 20.7 | 26.3 | 37 | 57.3 | 71.1 | 84.1 | 123 |

| M(Screw) | M4 | M8 | M8 | M10 | M12 | M20 | M20 | M24 | M36 |

N(Screw) | Ø58-M8 | Ø58-M8 | Ø58-M8 | Ø58-M8 | Ø58-M8 | Ø94-M10 | Ø94-M10 | Ø150-M12 | Ø150-M12 |

| R(Screw) | Ø28-M4 | Ø28-M4 | Ø58-M6 | Ø58-M6 | Ø58-M6 | Ø94-M8 | Ø94-M8 | Ø150-M10 | Ø150-M10 |

Pulling force(kgf) | 700 | 1000 | 1200 | 1800 | 2300 | 2800 | 3200 | 3700 | 5500 |

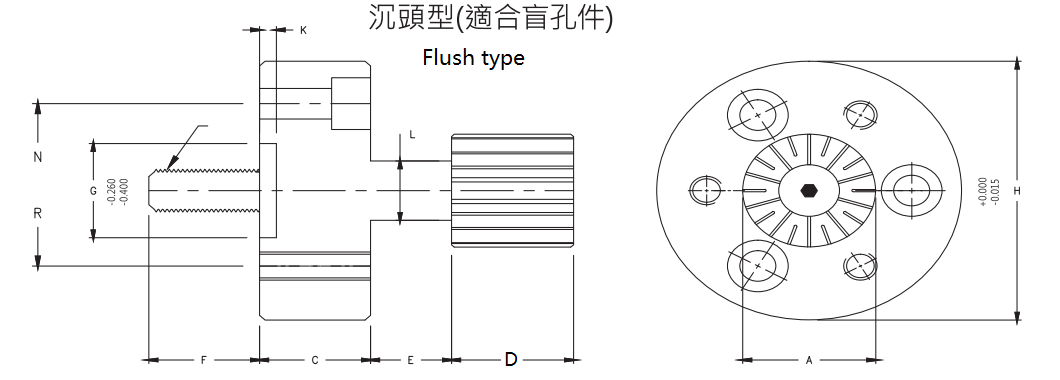

Flush type | 3A2 | 2C2 | 1C2 | 18C2 | 4C2 | 5C2 | 6C2 | 7C2 | 8C2 |

|---|---|---|---|---|---|---|---|---|---|

| A(Dia) | Min:16. | Min:22.0 | Min:28.5 | Min:40.0 | Min:51.0 | Min:73.0 | Min:89.0 | Min:101.0 | Min:143.0 |

| C | 20 | 20 | 20 | 20 | 20 | 25 | 25 | 30 | 30 |

| D | 26 | 32 | 38 | 45 | 50 | 60 | 69 | 78.5 | 99.5 |

| E | 14.6 | 15 | 15.5 | 15.3 | 14.8 | 25.3 | 24.7 | 25.2 | 24.6 |

| F | 20 | 22 | 30 | 31 | 36 | 36 | 37 | 47 | 22 |

| G | 40 | 40 | 40 | 40 | 40 | 60 | 60 | 100 | 100 |

| H | 75 | 75 | 75 | 75 | 75 | 120 | 120 | 180 | 180 |

| J | 11 | 15 | 20 | 26.5 | 37.5 | 55 | 74.5 | 86.5 | 124 |

| K | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| L | 12.6 | 14.1 | 20.7 | 26.3 | 37 | 57.3 | 71.1 | 84.1 | 123 |

M((Screw) | M4 | M8 | M8 | M10 | M12 | M20 | M20 | M24 | M36 |

N(Screw) | Ø58-M8 | Ø58-M8 | Ø58-M8 | Ø58-M8 | Ø58-M8 | Ø94-M10 | Ø94-M10 | Ø150-M12 | Ø150-M12 |

R(Screw) | Ø28-M4 | Ø28-M4 | Ø58-M6 | Ø58-M6 | Ø58-M6 | Ø94-M8 | Ø94-M8 | Ø150-M10 | Ø150-M10 |

| Pulling force(kgf) | 700 | 1000 | 1200 | 1800 | 2300 | 2800 | 3200 | 3700 | 5500 |

Subject to technology changes without prior information

Non-standard requirements can be made